Small engines power many different types of equipment, from lawnmowers and other outdoor products to generators, pressure washers and industrial applications. Small engines offer compact size, straightforward construction and efficient performance, and can last for many years if cared for properly. Before jumping into a maintenance routine, however, you must understand how small engines work and what they are to keep them running efficiently.

What Is a Small Engine?

A small engine is defined as an engine that produces less than 25 horsepower. Generally speaking, the larger the engine, the greater the horsepower.

Small engines are typically 2-stroke or 4-stroke components that power outdoor equipment like lawnmowers, tractors and generators as well as small vehicles like dirt bikes and mopeds.

History of the Small Engine

The evolution of the small engine began centuries ago, as manufacturers sought to produce engines with more power in reduced sizes. During the late 1700s, Scottish inventor James Watt, the namesake of the watt power unit and developer of the concept of horsepower, made the first innovations in steam engine design to make it slightly smaller and more efficient.

By the mid-1800s, the first combustion engines were developed. These smaller engines ran on gasoline and kerosene and were adopted by everyone from farmers to industrialists. In the 1900s, the manufacturing company Briggs & Stratton developed their revolutionary Type “P” engine, which was the first 4-stroke gasoline engine. It instantly became popular for its convenient, portable design and affordable price.

Later in the 1900s, Briggs & Stratton created the first lightweight, air-cooled, 2-stroke engine that revolutionized the lawn and garden industry. Today, many manufacturers produce small engines, as they are widely used in many different types of outdoor equipment and small vehicles.

How Does a Small Engine Work?

Small engines are a type of combustion engine, which runs on an explosion between fuel and a spark. The explosion creates heat energy that the mechanical parts in the engine use to power the equipment.

Power from 2-stroke and 4-stroke models is generated in much the same way. The steps in a 4-stoke process include:

- Intake stroke: Fuel and air enter the engine through the carburetor and are mixed together. The intake valve between the combustion chamber and the carburetor then opens to allow the fuel-air mixture to be forced into the cylinder bore while the pistons move downward.

- Compression stroke: When the piston gets to the bottom center, the intake valve closes and the piston returns to the top of the cylinder bore. During this stroke, the fuel-air mixture is compressed between the cylinder head and the piston.

- Power stroke: When the piston gets to the top, it’s ready to ignite the fuel. The spark plug enables high voltage that is discharged into the combustion chamber. The spark creates heat that ignites the gases and forces the piston back down in the cylinder bore.

- Exhaust stroke: When the piston gets to the bottom center again, the exhaust valve opens. The pistons travel back up the cylinder bore and force the spent combustion gases through the exhaust. Once the pistons reach the top, the exhaust valve closes, the intake valve opens and the 4-stroke process begins again.

A 2-stroke engine performs all the same steps but in only two piston strokes.

Different Types of Small Engines

Small engines are categorized by their engine process, which means there are two different types of small engines: 2-stroke and 4-stroke. Both types may be powered by gasoline or diesel fuel.

Examples of equipment powered by 2-stroke engines include:

- Leaf blowers

- Chainsaws

- Small outboard motors

- Mopeds

Examples of equipment powered by 4-stroke engines include:

- Lawnmowers

- Generators

- Pumps

- Motorcycles

Small Engine Replacement

If you’re having problems with your small engine, you must decide whether to repair or replace it. Newer engines or engines with minor operating issues may be worth repairing, while older engines with major problems might be better to replace.

Small Engine Maintenance Troubleshooting

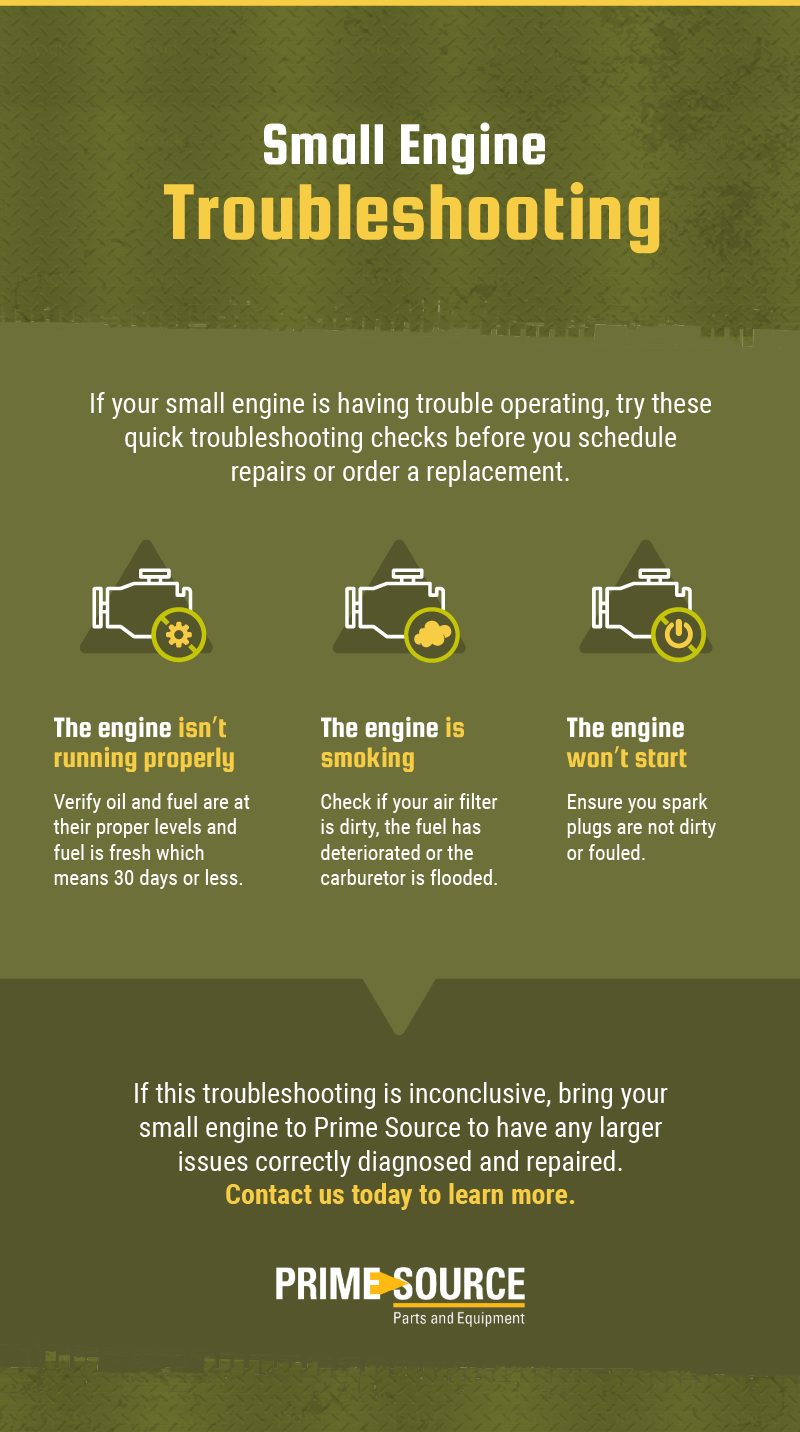

To determine whether repair or replacement is the right choice for your needs, try troubleshooting. A few quick checks can reveal a lot about what is going on with your small engine.

- Start by making sure that your oil and fuel are fresh and at their proper levels. If these fluids are dirty or low, the engine won’t run properly.

- If the engine is smoking, it could mean your air filter is dirty, the fuel has gone bad, or the carburetor is flooded. Examine each component to see if any of these issues are occurring.

- If your engine won’t start, check your spark plugs to see if they are disconnected or dirty. If your spark plugs look good, the ignition system may be the problem.

If these troubleshooting efforts are inconclusive, there may be a larger issue. Combustion engines rely on air, lubrication, compression and fuel to work, so engine problems will typically fall under one of those categories.

The best way to correctly diagnose your small engine issues is to bring it to a professional repair shop. Once they determine the severity of the issue, you can decide whether to replace it.

Contact Prime Source for Your Small Engine Services

At Prime Source, we offer small engine repair as well as small engine parts to help home and business owners in North Carolina keep their small engines in top condition and extend their life span. When you bring your small engine to Prime Source, our experienced technicians precisely identify the cause of the problems. From there, we can repair it for you or provide you with parts to get it working again.

As a single-source provider, we focus on exceptional customer service, and our technicians and sales staff bring many years of experience to the table. Contact us today to learn more about our small engine services.